Wood Anatomy Lab - Instruments

1. Sliding Microtome - Leica SM2010 R

It is a manually operated sliding microtome, designed as a low-maintenance tabletop instrument with roller-guided knife sledges and automatic section thickness feed. It is used for taking stem and wood sections. It has a stable, torsion-free basic design with micrometre feed system in a closed housing, protected from ingress of paraffin waste. The instrument has an ergonomically optimized specimen head position; the smooth-running knife sledge can be securely locked in 10 mm increments. The sectioning window can be adjusted to the specimen size. The cutting thickness can be adjusted within the range of 0.5 μm to 60 μm; the automatic feed functions in the range of 0.5 μm to 30 μm. Manual feed by pulling or pushing the feed lever. The instrument is either fitted with a blade holder for disposable blades. The blade holder and knife holder each have an integrated knife guard. In the knife holder a blade rail can also be inserted for holding disposable blades.

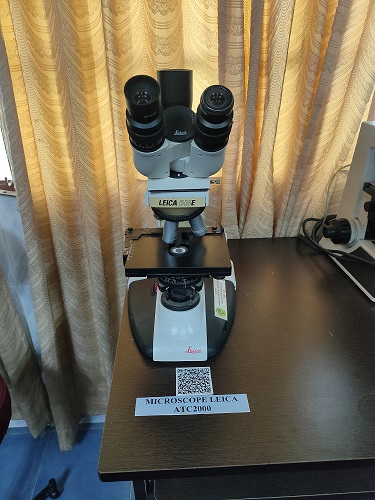

2. Microscope

It is used for viewing stem, wood and other microscopic sections. MoticTM Trinocular Microscope can serve as digital work station by integrating CMOS cameras and image analysing software. Binocular microscope is essential for a material science course like wood science for examining the microscopic sections. Its versatile stage and reflected light system work in combination to deliver high quality images of the most demanding specimens. The images can be magnified to 4x, 10x, 40x and 100x levels. The mechanical stage can be used for both transmitted and reflected light. It can be equipped with various specimen holders to accommodate mounted specimens of different diameters. The unique Reflected light LED illuminator provides brightfield, polarized light, and oblique illumination. This allows you to work with many different specimens with the same microscope configuration.

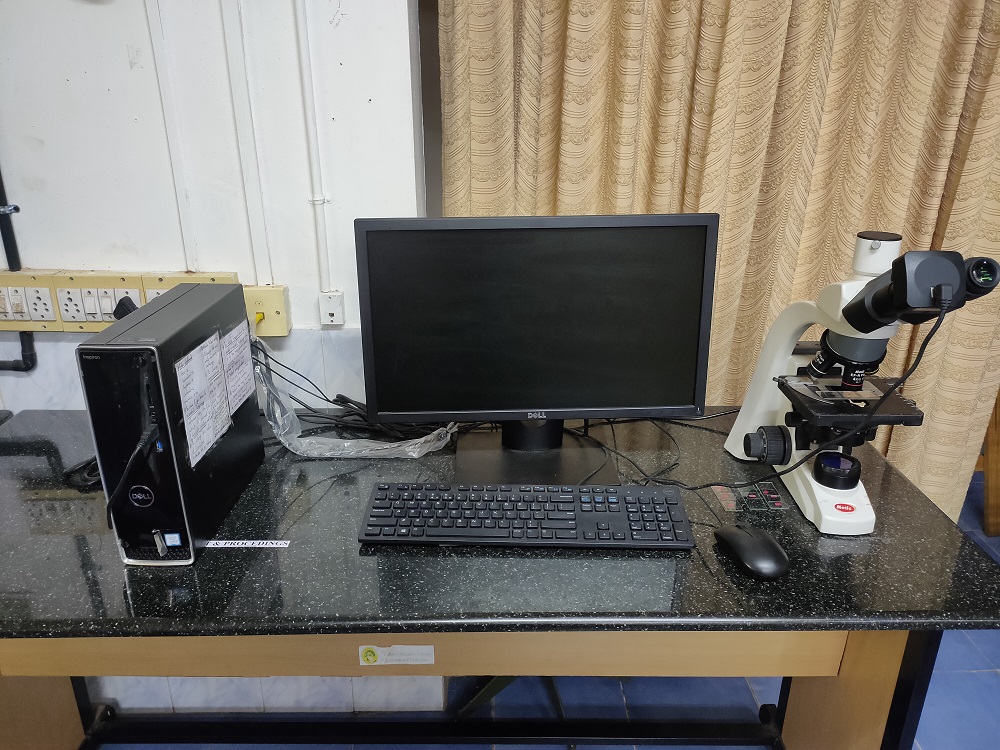

3. Image Analysis System

Image analysis system which composed of computer and trinocular microscope attached with a camera which is used to take photographs and measurements of anatomical sectional taken out of wood sample.

Non-destructive Testing Instruments

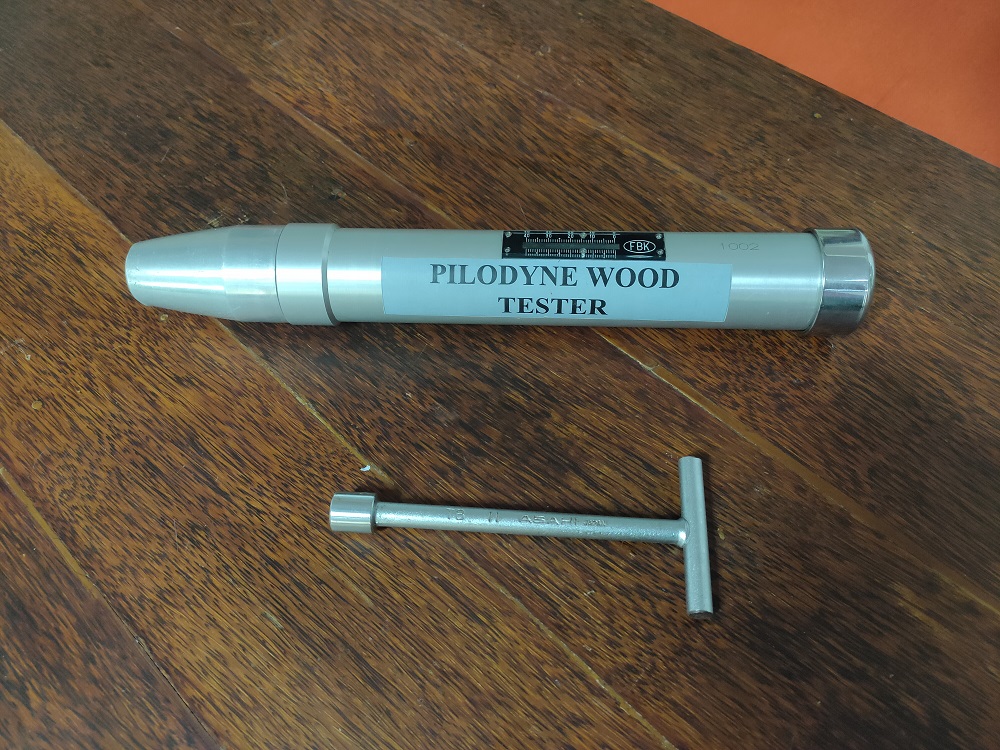

1. Pilodyn

Pilodyn wood density meter tester, was developed to determine the density and strength of dead and living wood. Invisible soft rot can be detected rapidly and objectively in an easy non-destructive way and the reduction in strength associated with it can be determined.

2. Tree Sonic Timer

Tree Sonic microsecond timer is designed for tree stiffness prediction. It measures the stress wave time between a start and a stop transducer.

Tree Ring Analysis-Instruments

1. Tree Ring Station- L I N T A B™ Series 6

It is a linear tree-ring measuring stage for stem disks, sections or increment cores. LinTab™ along with software “TSAP-Win™” is very useful for efficient and accurate analysis of tree rings. Trinocular stereo microscope with stand, CCD camera and led spotlight also attached to the tree ring station for the real-time capturing of the images of the sections.

2. Increment Borer

Increment borer is a specialized tool used to extract a section of wood tissue from a living tree with relatively minor injury to the plant itself. The tool consists of a handle, an auger bit and a small, half circular metal tray (the core extractor) that fits into the auger bit; the last is usually manufactured from carbide steel. The samples collected from tree are used for tree ring analysis as well as for anatomical studies.

Wood Workshop Instruments

1. Spindle Moulder

A spindle moulder also goes by the name of wood shaper that is used for milling profile on wooden billets. The woodworking spindle moulder is able to accommodate different sized blanks by adjusting the spindle. Woods are trimmed and shaped in the spindle moulder machine that make them suitable for a wide array of applications, like windows, frames, doors, shutters, etc.

2. Tenoning Machine

Tenoning machines use cutter heads and/or saw blades to form projections (tenons) on pieces of stock. Each tenon can be inserted into a cavity (mortise) on another piece of wood to form a mortise and tenon joint.

3. Drill Presses

A drill press is a wood cutting machine that uses a multiple-cutting-edged rotating tool to remove wood and produce a hole in the stock. Drilling machine is vertically arranged with the tools having variable speeds and feeds. They may also have multiple spindles for gang drilling. The most commonly used drilling machine is a single-spindle, floor-mounted, belt-driven machine for non-production drilling.

4. Jig saw

Jig saws are useful for precision-cutting intricate curves and patterns on thin stock. They have thin blades that continuously running in circulation motion to make cut.

5. Basic router

Routers are used for cutting and shaping decorative pieces, making frame and panel doors, and milling moldings. Routers have spindles that spin variously shaped, small-diameter cutting tools at high speeds. The tool or bit, which is usually made out of high-speed steel or carbide, is held in a collet chuck and protrudes through a flat, smooth base that slides over the surface of the work. The tool-spindle axis usually is vertical.

6. Chain Mortiser

Mortising machines use boring bits or mortising chains to cut cavities in pieces of stock. These cavities are often used in mortise and tenon joints

7. Belt Sanders

Belt sanders used to smooth the wood surface for better finishing. Belt sanders finish stock by using a coated abrasive surface to remove material. This machine uses a system of pulleys to move the abrasive material across the stock. The wood is fed manually into the machine or the sanding belt is pressed toward the wood, which is located on a working table.

8. Vertical Band Saw

Vertical band saw uses thin, flexible, continuous steel strips with cutting teeth on one edge. They are used primarily for cutting, timber and wood planks. There are two types of band saws; horizontal and vertical contour band saws. In vertical band saw, the blade runs on two pulleys, driver and idler, and through a work table where wood is manually fed. Automatic feeds can be used for production cutting; however, this machine is usually considered a manual feed tool.

9. Planer

A planer is used to shave wood from the surface of boards. They are used to change a rough surface in to flat and smooth, or to reduce its thickness. The blades are carefully positioned so that the material is left flat and even after a pass is made. In addition, the blades can be adjusted. This allows the user to cut a specific amount of material with each pass.

Other Instruments

1. Specific Gravity Measurement Kit

Specific gravity measurement kit is Simple specific gravity meter based on precision balances which is used to measure the specific gravity of wood directly.

2. Moisture meter

This digital moisture analyser used to measure moisture content in the wood samples. Built-in calibration check ensures readings are accurate and backlight provides visibility in low-light conditions.

3. Basic Analytical Mill

Basic Analytical mill is used to powder the samples and also serves the purpose of through mixing the two powders. Batch mill has 2 different grinding procedures: 1. Impact grinding of hard, brittle or non-elastic grinding materials with high-grade stainless-steel beater; 2. Cutting grinding for pulverizing soft, fibrous materials with a cutting blade. This beater can be used for a Mohs hardness up to 6. Moist and gluey materials can be pulverized by adding water. Grinding chamber made of Tefcel (PTFE, glass fibre-reinforced) with stainless steel inlet (1.4571), useful volume 80 ml (incl. with delivery).

4. Tube Disperser- IKA ULTRA-TURRAX

The IKA ULTRA-TURRAX Tube Disperser assures the best stirring, dispersing, grinding and homogenisation results and has been devised in particular for the safe processing of infectious, toxic or odour-intensive samples. The sealable disposable tubes have been optimised for various applications. They reduce the amount of cleaning required and rule out any risk of cross-contamination.

5. Automatic Tissue Processing Unit